文章來源:中國寶武(wu) 發布時(shi)間(jian):2019-07-13

1.項目背景

上海(hai)寶(bao)鋼(gang)化工有限(xian)公司四期(qi)廢水處(chu)理(li)裝(zhuang)置為寶(bao)鋼(gang)四期(qi)焦爐配套建設(she)裝(zhuang)置,四期(qi)廢水裝(zhuang)置工藝(yi)為A/O/A/O工藝(yi)+超濾(lv)+納(na)濾(lv)+反滲透膜處(chu)理(li)工藝(yi),反滲透產水作為工業(ye)(ye)水回用(yong)(yong),濃(nong)水用(yong)(yong)于燒(shao)結系(xi)統(tong)拌料和(he)干法(fa)脫硫(liu)進(jin)行利(li)用(yong)(yong)。為消除濃(nong)水對燒(shao)結的(de)(de)影(ying)響(xiang),上海(hai)寶(bao)鋼(gang)化工有限(xian)公司對焦化濃(nong)水的(de)(de)回用(yong)(yong)途徑(jing)進(jin)行重新優化。通(tong)過“四期(qi)納(na)濾(lv)和(he)反滲透濃(nong)水膜法(fa)試驗研(yan)究”科(ke)研(yan)項目,采用(yong)(yong)膜分離(li)(li)技術將濃(nong)水中的(de)(de)氯離(li)(li)子(Cl-)和(he)硫(liu)酸根離(li)(li)子(SO42-)從系(xi)統(tong)中徹底分離(li)(li),得到氯化鈉和(he)硫(liu)酸鈉工業(ye)(ye)級結晶(jing)鹽,最終實現廢水零排放、分鹽的(de)(de)資源化利(li)用(yong)(yong)。

2.工藝介紹

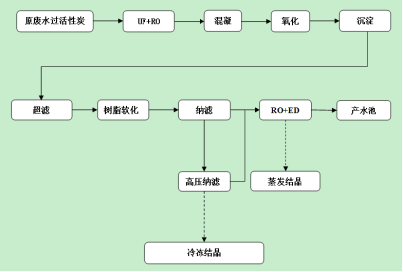

焦化廢水零(ling)排放資源化利用(yong)工藝包(bao)含三大(da)部(bu)分:預處理(li)部(bu)分,膜(mo)濃縮分鹽(yan)部(bu)分和結(jie)晶出鹽(yan)部(bu)分。

膜分鹽濃(nong)縮技術工藝流程圖

1)預處理(li)部分(fen)(fen)(fen):包含活(huo)性(xing)炭吸附(fu)、超濾(lv)(lv)(lv)、除硅、氟和離(li)子(zi)交(jiao)換工藝,主(zhu)要除去(qu)廢(fei)水(shui)中的(de)懸浮物、濁(zhuo)度(du)(du)、色度(du)(du)、COD、硅、氟和鈣(gai)鎂硬度(du)(du)等(deng)(deng),原水(shui)經過(guo)預處理(li)后(hou)(hou),達到(dao)進(jin)入膜(mo)(mo)濃縮系統(tong)要求(qiu)。活(huo)性(xing)炭過(guo)濾(lv)(lv)(lv)作為(wei)水(shui)處理(li)脫(tuo)鹽(yan)系統(tong)前(qian)處理(li)能夠吸附(fu)前(qian)級(ji)過(guo)濾(lv)(lv)(lv)中無(wu)法去(qu)除的(de)余(yu)氯,可有效保(bao)證(zheng)(zheng)后(hou)(hou)級(ji)設備使(shi)用壽(shou)命,特別是防止后(hou)(hou)級(ji)反(fan)滲透膜(mo)(mo)、離(li)子(zi)交(jiao)換樹(shu)脂(zhi)(zhi)等(deng)(deng)的(de)游離(li)態余(yu)氯中毒污染,還可以進(jin)一(yi)(yi)步(bu)降(jiang)低RO進(jin)水(shui)的(de)SDI值,保(bao)證(zheng)(zheng) SDI≤5,TOC≤2.0ppm。超濾(lv)(lv)(lv)處理(li)工藝超濾(lv)(lv)(lv)技(ji)術是通過(guo)膜(mo)(mo)表面的(de)微孔結(jie)構對物質(zhi)進(jin)行(xing)選擇性(xing)分(fen)(fen)(fen)離(li),當廢(fei)水(shui)在(zai)一(yi)(yi)定(ding)壓力(li)下流經膜(mo)(mo)表面時,小分(fen)(fen)(fen)子(zi)溶質(zhi)透過(guo)膜(mo)(mo),而大(da)(da)(da)分(fen)(fen)(fen)子(zi)物質(zhi)則被截留,使(shi)原液(ye)中大(da)(da)(da)分(fen)(fen)(fen)子(zi)濃度(du)(du)逐(zhu)漸提高,從(cong)而實(shi)現(xian)大(da)(da)(da)、小分(fen)(fen)(fen)子(zi)的(de)分(fen)(fen)(fen)離(li)、濃縮、凈化。大(da)(da)(da)孔交(jiao)聯樹(shu)脂(zhi)(zhi),吸附(fu)能力(li)高,在(zai)處理(li)廢(fei)水(shui)時,讓水(shui)從(cong)陽離(li)子(zi)交(jiao)換樹(shu)脂(zhi)(zhi)吸附(fu),陽離(li)子(zi)交(jiao)換樹(shu)脂(zhi)(zhi)中的(de)氫離(li)子(zi)被交(jiao)換到(dao)水(shui)中去(qu),使(shi)水(shui)得到(dao)凈化,樹(shu)脂(zhi)(zhi)長期運行(xing)可以通過(guo)再生重復使(shi)用,運行(xing)效果穩定(ding)準確。

活性炭吸(xi)附塔 超濾裝置(zhi) 樹脂軟(ruan)化裝置(zhi)

2)膜(mo)濃(nong)(nong)縮(suo)分(fen)鹽(yan)部分(fen):廢水(shui)(shui)進(jin)(jin)(jin)入膜(mo)濃(nong)(nong)縮(suo)系統,利用反(fan)滲透進(jin)(jin)(jin)行(xing)濃(nong)(nong)縮(suo),產生淡水(shui)(shui)回用;利用納濾進(jin)(jin)(jin)行(xing)分(fen)鹽(yan),將廢水(shui)(shui)中(zhong)的氯(lv)化鈉(na)(na)和硫酸鈉(na)(na)進(jin)(jin)(jin)行(xing)分(fen)離,同時對硫酸鈉(na)(na)進(jin)(jin)(jin)行(xing)濃(nong)(nong)縮(suo),得到(dao)濃(nong)(nong)度(du)為10%-15%的硫酸鈉(na)(na)濃(nong)(nong)縮(suo)液;之后利用反(fan)滲透和電驅(qu)動膜(mo),對氯(lv)化鈉(na)(na)溶液進(jin)(jin)(jin)一步(bu)濃(nong)(nong)縮(suo),得到(dao)濃(nong)(nong)度(du)為10%-15%的氯(lv)化鈉(na)(na)濃(nong)(nong)縮(suo)液。

納濾、反滲透裝置

3)結(jie)(jie)晶(jing)(jing)出(chu)鹽(yan)(yan)部分:對(dui)氯(lv)化(hua)鈉濃縮(suo)液進(jin)行蒸發(fa)結(jie)(jie)晶(jing)(jing),對(dui)硫酸鈉濃縮(suo)液冷凍結(jie)(jie)晶(jing)(jing),得(de)到高純度的工(gong)業(ye)級(ji)結(jie)(jie)晶(jing)(jing)鹽(yan)(yan)產(chan)品(pin),同時產(chan)生符合(he)寶鋼工(gong)業(ye)水(shui)指標的回用水(shui)。

氯化鈉結晶鹽(yan) 硫酸鈉結晶鹽(yan)

3.項目成果

焦化(hua)廢(fei)水(shui)(shui)零排放(fang)資源化(hua)利(li)用(yong)項目對(dui)生(sheng)化(hua)出水(shui)(shui)進一步(bu)(bu)處理,廢(fei)水(shui)(shui)經(jing)(jing)氧化(hua)及軟(ruan)化(hua)預處理+膜分(fen)離及濃縮(suo)+分(fen)質結(jie)(jie)晶工(gong)藝,濃水(shui)(shui)經(jing)(jing)過高(gao)(gao)壓膜和冷凍結(jie)(jie)晶工(gong)藝,得到合格工(gong)業(ye)(ye)(ye)級硫(liu)(liu)酸鈉(na)結(jie)(jie)晶鹽(yan)產品(pin);分(fen)鹽(yan)產水(shui)(shui)再經(jing)(jing)過提鹽(yan)膜處理系(xi)統和電滲析和MVR(機械蒸(zheng)汽再壓縮(suo)蒸(zheng)發(fa)結(jie)(jie)晶)后得到工(gong)業(ye)(ye)(ye)級氯化(hua)鈉(na)結(jie)(jie)晶鹽(yan)。分(fen)質結(jie)(jie)晶得到的硫(liu)(liu)酸鈉(na)和氯化(hua)鈉(na)工(gong)業(ye)(ye)(ye)鹽(yan)品(pin)質較好,可以滿足工(gong)業(ye)(ye)(ye)鹽(yan)標準,產水(shui)(shui)可以回用(yong)于(yu)生(sheng)產工(gong)藝,水(shui)(shui)回用(yong)率進一步(bu)(bu)提高(gao)(gao),實現近零排放(fang),實現水(shui)(shui)資源高(gao)(gao)效(xiao)循環利(li)用(yong)。

4.應用前景

隨著生態文明建(jian)設(she)(she)和產(chan)(chan)業(ye)不斷升(sheng)級, 政府對(dui)水資源消耗總量和強(qiang)度雙控日益嚴格,中水回用(yong)和廢水零排(pai)放成(cheng)為(wei)工業(ye)企業(ye)基本要求。目(mu)(mu)前焦化(hua)廢水“零排(pai)放”項目(mu)(mu)以生產(chan)(chan)雜鹽為(wei)主,雜鹽作為(wei)危廢無法(fa)處置。上海(hai)寶鋼(gang)化(hua)工有限公(gong)司在焦化(hua)廢水資源化(hua)利用(yong)項目(mu)(mu)中形成(cheng)了自己的“零排(pai)放”核(he)心技(ji)(ji)術(shu),生產(chan)(chan)工業(ye)鹽和無水硫酸鈉產(chan)(chan)品,具有廣(guang)闊(kuo)的應(ying)用(yong)前景(jing),并將極大的推(tui)動國內焦化(hua)廢水回用(yong)領域的技(ji)(ji)術(shu)進步。目(mu)(mu)前應(ying)用(yong)該技(ji)(ji)術(shu)的示范工程已(yi)經(jing)在建(jian)設(she)(she)中。

【責任編輯:李凡】